As a member of the local PV power supply chain, Brave C&H Co., Ltd., the only local precision screen manufacturer listed on the over-the-counter market, has been dedicated to the R&D on new processes, helping major PV-cell manufacturers to develop high-performance PV cells featuring higher conversion rates, higher printing endurance, and lower production costs, in order to contribute to the development of the green-energy industry.

The global outlook of green energy has been improving markedly in recent years. In a year-end report for 2018, BNEF points out that along with the increase in global installation capacities, the generation costs for renewable energy, even without subsidies, have dropped below that of coal- and natural gas-fired power, thanks to its growing technological maturity and China’s decision to lower its subsidies.

Faced with China's 531 new policy and the "Top Runner Program," it has become imperative for PV-cell manufacturers to raise the conversion efficiency of PV cells, prompting them to embrace the SE (selective emitter) process in a rush. Brave C&H is the first Taiwanese precision screen manufacturer to employ the advanced process, which was already developed four years ago.

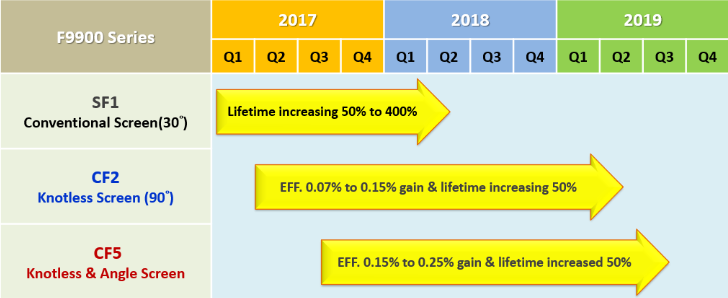

In order to cope with the rapid change in market needs, the R&D team of Brave C&H has invested significantly in high-technology process equipment and precision detection equipment for four years, successfully developing cutting-edge PI process technology and rolling out conventional screen (SF1), knotless screen (CF2), and knotless & angle screen (CF5), which boast an extremely thin finger opening, high printing endurance, resistance of swelling and deformation, and precision size. The excellent features plus vigorous marketing, has enabled the company to land a full backlog of orders, including from Taiwan, China, Korea, India, and Southeast Asia.

The success of the PI process is credited to the SF1 conventional screen’s long screen-printing lifetime which is 30-100% longer than that of the traditional emulsion process, plus the significant silver paste saving and the higher conversion rates. The CF5 knotless & angle screens can help customers achieve up to 20% paste saving and is the only knotless & angle screen compatible with the SE process. Unlike the traditional knotless screens, the CF5 knotless & angle screens can be used with the SE process to help customers to lower their production costs and increase their products’ conversion rates.

Adhering to the management and value concept of integrity, quest for excellence, and co-prosperity with customers, Brave C&H has been dedicated not only to the technological improvements of its products but also to the increase of conversion rates and the lowering of production costs via its close cooperation with customers and paste suppliers. Via constant innovation, the company, which is seen as the bellwether of the local screen industry, is confident of its prospects on the PV-cell market, which harbors significant potential.

(Photo Credit: Brave C&H)